Dealing with the Tesla approved body shop has been quite a headache. Tesla Motors club user wk057 a Tesla model S owner himself wants to build an awesome solar storage system.

Benchmarking The Tesla Model S A Tour Of Ricardo Engineering S Teardown Laboratory Copper Rotor Induction Motor

Pop off the panel on the side of the tunnel using a cloth maybe and the flat-head screwdriver.

Tesla car disassembly. As of mid-2019 Tesla has eleven shops in the USA. Okay the hard part is over. After the welding comparison Sandy shares that he views the Model Y as a pretty good build which is high praise considering the number of teardowns.

Once unplugged place the car back in P and safely exit the vehicle. It sells vehicles under its Tesla Motors division and stationary battery pack for home commercial and utility-scale projects under its Tesla. CleanTechnica via Autoline The automakers that would compete with Tesla.

Now you can unplug the parking brake motor. Pop the retainers holding the bottom plastic use your fingers to take off the couple of electrical connectors. Cross Car Beam Remove and Replace Assembly - Frame - Instrument Cluster Remove and Replace Trim - Touch Screen Surround Remove and Replace Face Level Vent - Drivers - Outer Remove and Replace Face Level Vent - Drivers - Inner Remove and Replace Face Level Vent - Front Passengers - Outer Remove and Replace.

That hope is more of a dream but I was surprised by how it happened. Well introduction you to. Teslas hope seems to be that the two polescalled A and B in the pictures in small blue font of each of the two relays will take 24 of the 48 amps of that 120V leg.

The onboard computer warned the occupants to exit. Please reference your VIN and which Body Shop you are working with so we can promptly assist. They must hold down the brake pedal and place the car in N hold the selector there for a few seconds.

Welcome to episode 15 of Munros Tesla Model Y Performance teardown where Munro Associates CEO Sandy Munro walks us through what a tailor welded blank is why its useful where its used on the Model Y and where it wasnt used on the Model 3. I wont go into all the details but it took a frustrating 4 weeks from receiving the car to completing disassembly of the necessary areas to evaluate for additional damage and order parts. When the car is placed in N the parking brake motors will retract.

It sells vehicles under its Tesla Motors division and stationary battery pack for home commercial and utility-scale projects under its Tesla. Well introduction you to the motor components differential oil. For several years Tesla has been working to make cars more and more autonomous in order to reduce accidents and provide optimum driver assistance.

In this ALL EV Canada video we teardown a Tesla Model 3 rear electric motor drive assembly. Semi-autonomous cars use lots of sensors to approximate autonomous driving like cameras radar lidar and ultrasonic sensors in order to explore the environment around the car. Hes purchased a battery pack from a salvaged Tesla.

Put a light in. Tesla is a transportation and energy company. Tesla continues to work to reduce the amount of cobalt in its batteries and with its sourcing in Canada this is largely a non-issue from a supply chain standpoint.

Our team will work around the clock until the Model Y is completely disassembled. All of this sensor-derived information must be grouped and this is where. Of the additional parts ordered 3 parts remain out of stock.

It is important to never touch the throttle during this process. The flat head is to pop plastic rivets so a standard 14 blade. After going over a number of other parts they can see at this stage of disassembly the guys decide to go a bit further and remove the lighting unit.

The Munro team struggled mightily to disassemble the Tesla pack so Sandy wonders whether it will be as easy to repurpose for post-EV uses as those in. In both cases the occupants walked away unharmed thanks to the cars safety features. If you just short the battery it will trigger the Automated Rapid Disassembly process.

Now its time to. The team will dig. This reveals the metal bars that the feeding.

A Tesla Model 3 in the process of being disassembled at Munro Associates Image. In 2013 two extremely unusual Model S collisions resulted in underbody damage that led to car fires. Right front fender support bumper beam and bolts for the bumper beam.

Ive been in contact with the Tesla. These shops even stock some parts like pre-painted bumper covers to speed the repair. Having said that the toxicity.

Tesla is a transportation and energy company. Tesla has also created some of its own Body shops in high-volume areas. The additional parts were ordered 2 weeks ago.

These incidents unfortunately received more national headlines than the other 200000 gasoline car fires that happened last year in North America alone. Youll have to bypass the battery management system and then securely clamp both high voltage leads to a very substantial copper bus bar. The incoming L2I did all my analysis on L2 because it was closer to the edge of the board spade is split into two smaller bars that have a cross-sectional area.

On April 14 a live stream of a rapid disassembly of the vehicle will begin at 8 AM.

Tesla Model 3 Battery Details Revealed In Partial Teardown And Analysis

Tesla Model 3 Battery Details Revealed In Partial Teardown And Analysis

Tesla Battery Teardown In 9 Minutes Video

Tesla Battery Teardown In 9 Minutes Video

Tesla Model 3 Teardown Of Vcfront Front Body Controller Youtube

Tesla Model 3 Teardown Of Vcfront Front Body Controller Youtube

Tesla Modell S Us 70k Beste Luxus Autos Tesla Model X Vehicule Hybride Voiture

Tesla Modell S Us 70k Beste Luxus Autos Tesla Model X Vehicule Hybride Voiture

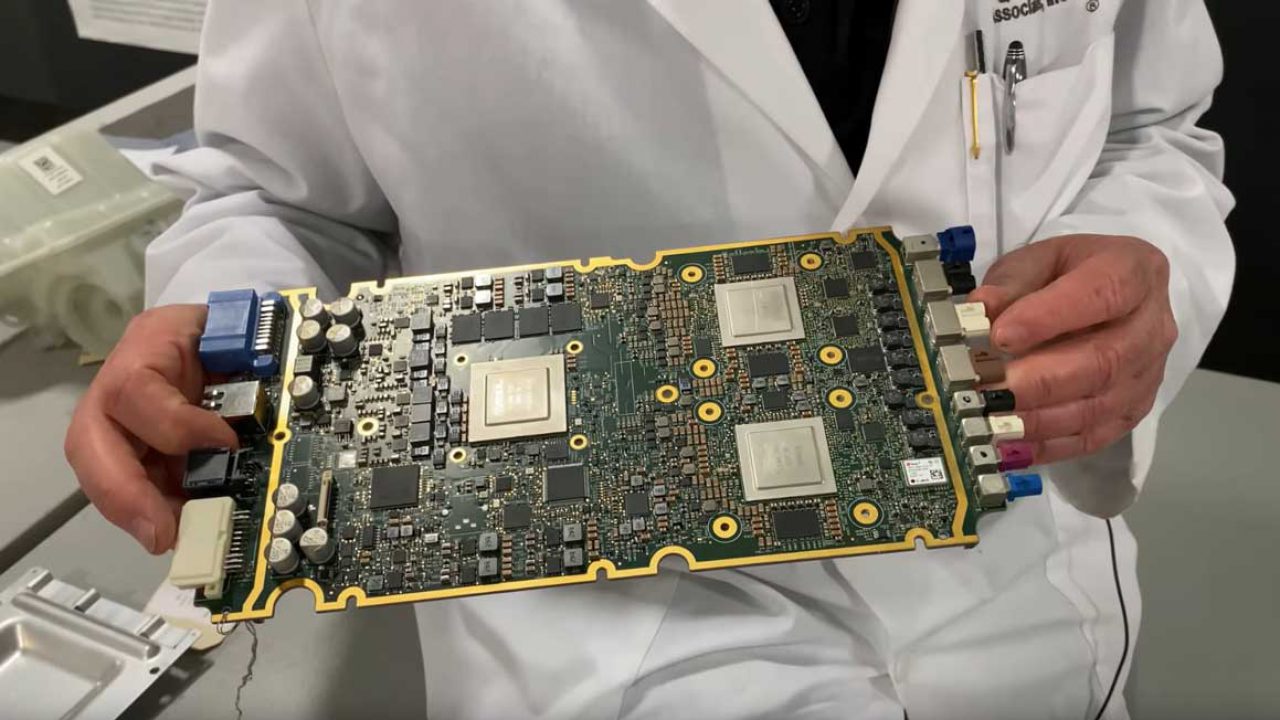

Teardown Tesla S Hardware Retrofits For Model 3 Ee Times Asia

Teardown Tesla S Hardware Retrofits For Model 3 Ee Times Asia

Sandy Munro Finds Fun Tesla Model Y Easter Egg In Octovalve

Sandy Munro Finds Fun Tesla Model Y Easter Egg In Octovalve

Here S What 7 000 Of Damage Looks Like On A Tesla Model 3

Here S What 7 000 Of Damage Looks Like On A Tesla Model 3

Teardown Tesla S Hardware Retrofits For Model 3 Ee Times Asia

Tesla Model S Teardown With Light Harmonic Premium Audio Upgrade Youtube

Tesla Model S Teardown With Light Harmonic Premium Audio Upgrade Youtube

Environmental Aspects Of The Electric Car Wikipedia

Environmental Aspects Of The Electric Car Wikipedia

Tesla Model Y Teardown First Impression By Sandy Munro Welcome To Red Rocks Online

Tesla Model Y Teardown First Impression By Sandy Munro Welcome To Red Rocks Online

New Model 3 Teardown Reports Tesla Has 6 Year Lead Over Competitors In Electronics Evbite

New Model 3 Teardown Reports Tesla Has 6 Year Lead Over Competitors In Electronics Evbite

Tesla Certified Shops Must Do Teardown Blueprint Only Get Two Chances At Parts Orders Repairer Driven Newsrepairer Driven News

Tesla Certified Shops Must Do Teardown Blueprint Only Get Two Chances At Parts Orders Repairer Driven Newsrepairer Driven News

Tesla Model 3 Teardown Guru Finds Good Bad Construction Wardsauto

Tesla Model 3 Teardown Guru Finds Good Bad Construction Wardsauto

Benchmarking The Tesla Model S A Tour Of Ricardo Engineering S Teardown Laboratory Copper Rotor Induction Motor

Tesla Model 3 Teardown And Benchmarking Report Marklines Automotive Industry Portal

Tesla Model 3 Teardown And Benchmarking Report Marklines Automotive Industry Portal

Absolutely Stunning Model Y Teardown Shows Step Change In Innovation

Absolutely Stunning Model Y Teardown Shows Step Change In Innovation

Tesla Model 3 Inside Out Autoline After Hours 417 Youtube

Tesla Model 3 Inside Out Autoline After Hours 417 Youtube

Tesla Model 3 Motor Tear Down All Ev Youtube

Tesla Model 3 Motor Tear Down All Ev Youtube

Komentar

Posting Komentar